An electrical connector is a device designed for connecting and transmitting electronic or electrical signals. It is widely used in various fields including electronic equipment, communication networks, and power systems. Electrical connectors come in a wide variety of types, which can be classified based on different criteria.

I. Classification by Shape

- Circular Connectors: Characterized by a circular profile, these connectors typically adopt a threaded coupling mechanism. Featuring excellent waterproof performance and high mechanical strength, circular connectors are extensively used in aerospace, automotive electronics, and other demanding sectors.

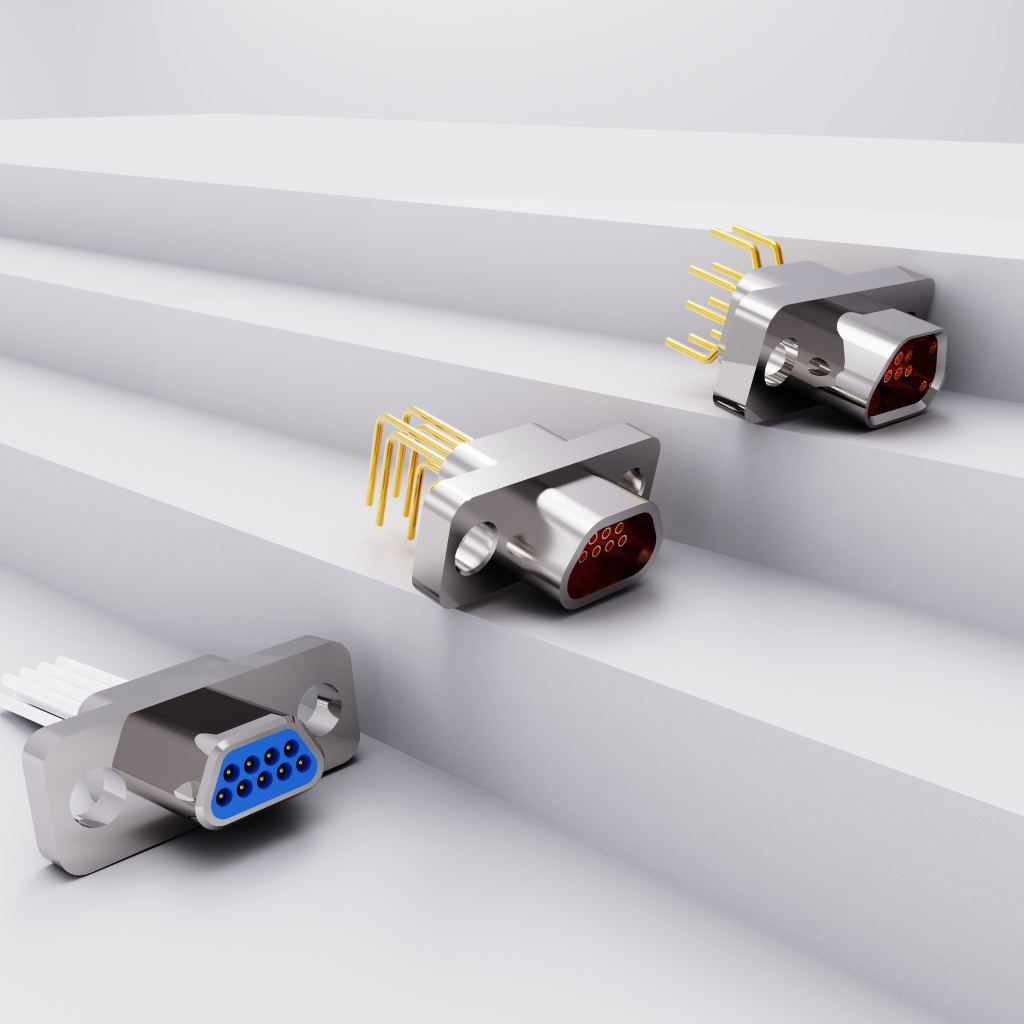

- Rectangular Connectors: With a rectangular form factor, these connectors boast diverse structural designs, some utilizing a snap-fit mechanism while others adopting alternative connection methods. Rectangular connectors are widely deployed on printed circuit boards (PCBs) of electronic devices and in industrial automation equipment applications.

II. Classification by Application

- Signal Connectors: Primarily engineered for transmitting low-voltage and low-current signals such as audio and video signals. Signal connectors usually incorporate a miniaturized design to meet the space constraints of electronic devices.

- Power Connectors: Dedicated to the transmission of high-voltage and high-current electrical signals. These connectors are equipped with larger sockets and pins to accommodate high-power transmission requirements. They are widely used in power systems and industrial equipment.

- Data Connectors: Designed for digital signal transmission, including data exchange between computers and network communications. Data connectors typically deliver high transmission rates and strong anti-interference capability to ensure reliable data transmission.

- Fiber Optic Connectors: Used for fiber optic cable connections in fiber optic communication systems. Fiber optic connectors offer advantages such as low insertion loss, high transmission capacity, and immunity to electromagnetic interference (EMI), making them ideal for communication networks and data centers.

III. Classification by Connection Method

- Threaded Connectors: Connection is achieved via a threaded structure, providing superior mechanical strength and anti-loosening performance. Threaded connectors are commonly used in applications requiring high reliability and waterproof capability, such as automotive electronic systems and aerospace equipment.

- Snap-fit Connectors: These connectors utilize a snap-lock structure for mating, featuring the characteristics of quick connection and disconnection. They are widely applied in consumer electronics products like computers and mobile phones, as well as in industrial automation equipment.

IV. Classification by Special Performance

- Sealed Connectors: Equipped with excellent sealing performance, these connectors can prevent moisture, dust, and other external contaminants from damaging the internal components.

- High-temperature Connectors: Capable of operating stably in high-temperature environments, they are suitable for electronic devices that must withstand elevated temperature conditions.

- Filtered Connectors: Integrated with built-in filters, these connectors can eliminate noise and interference from signals, thereby improving signal transmission quality.

How to Select the Right Electrical Connector

When selecting a suitable electrical connector, the following factors must be taken into consideration:

- Operating Environment: First and foremost, determine the operating conditions of the connector, including temperature, humidity, vibration, and other environmental factors. Select the appropriate connector type and material based on these specific conditions.

- Usage Mode: Clarify the intended usage mode of the connector—for example, whether it is a unidirectional or bidirectional connection, and whether frequent mating and unmating are required. These factors will influence the selection of the connector’s structure and materials.

- Size and Shape: Electronic devices generally demand a compact design, so it is necessary to choose a connector with a small footprint and appropriate shape. Additionally, consider the spatial layout and ease of installation of the connector.

- Electrical Performance: Select a connector with corresponding electrical performance based on the type and requirements of the transmitted signal. For instance, high-speed data transmission requires data connectors with high transmission rates and strong anti-interference capability; whereas power transmission applications call for power connectors capable of withstanding high voltage and high current.

- Durability: Connectors are required to withstand multiple mating cycles and long-term use. Therefore, prioritize durability and reliability during selection, and opt for connectors with superior material quality and robust design.

- Supplier Reputation and Service: Choosing a supplier with a solid reputation and high-quality service is conducive to ensuring connector quality and on-time delivery. Establishing a good cooperative relationship with suppliers can also provide access to better technical support and after-sales service.

In conclusion, selecting the right electrical connector requires a comprehensive consideration of multiple factors, including operating environment, usage mode, size and shape, electrical performance, durability, as well as supplier reputation and service. By taking all these factors into account, one can select the optimal electrical connector that best meets specific application requirements.

.png)

-1.png)