What is a micro-rectangular electrical connector?

The micro-rectangular electrical connector is a kind of miniaturized and high-density rectangular electrical connector, which is mainly used to achieve electrical connection of circuits in limited spaces. It is widely applied in fields with stringent requirements for volume, weight and reliability, such as aerospace, military industry, communications, medical equipment and precision instruments.

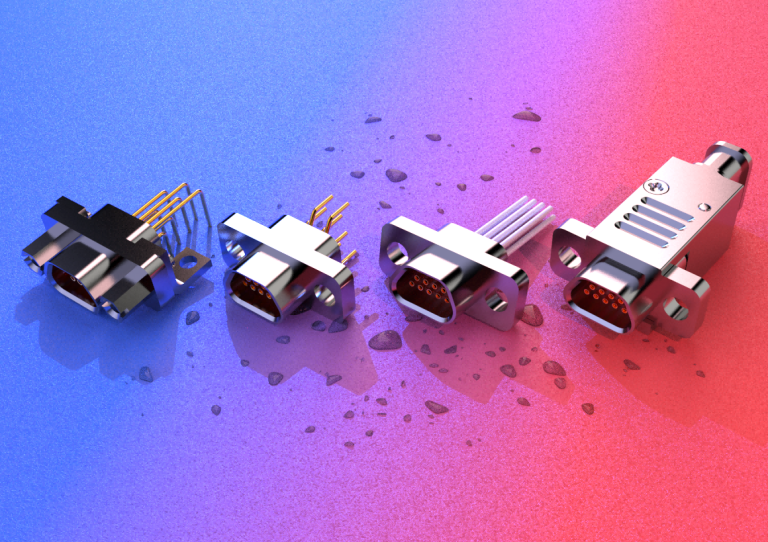

Micro Rectangular Connectors

Core Advantages

Mini & High-Density: Compact size with 1.27/2.0/2.54 mm pin spacing; more contacts for multi-circuit signal and power transmission.

High Reliability: Precision contacts (stranded pins, crown spring sockets) resist vibration and shock; durable in extreme temperatures, humidity and salt spray.

Lightweight: Aluminum alloy/engineering plastic shells, ideal for aerospace and portable devices.

Standardized & Modular

: Configurable contact counts; compliant with MIL-DTL-83513andGB/T 2351or full interchangeability.

Key Classifications

By Locking Method: Thread, snap-in, crimp locking

By Transmission Type: Signal (low-current), Power (high-current), Hybrid (simultaneous signal/power transmission)

By Protection Level: General-purpose; Hermetic (IP67+ rating, suitable for humid/dusty environments)

Quality system And Reliability test

As a manufacturer of micro-rectangular electrical connectors, we prioritize the optimization of quality management systems and reliability testing procedures to ensure customer satisfaction with our product quality.

1. As a manufacturer of micro-rectangular electrical connectors, we prioritize the optimization of quality management systems and reliability testing procedures to ensure customer satisfaction with product quality. Our factory is equipped with self-developed patented new automated machinery for twisted contacts, and boasts a comprehensive production system, along with certifications including ISO 9001 and CE.

2. Design and Plan Quality Processes:

When designing and planning quality processes, we need to consider all stages of production and testing comprehensively. This encompasses aspects such as raw material procurement and inspection, process control, product testing and validation, as well as packaging and shipping of the final products. Each stage should have appropriate quality control measures and records in place to ensure effective quality control.

Delivering Excellence in Electrical Connector Manufacturing: A Comprehensive Overview of Our Production Process and Quality Assurance

By addressing these issues, we will be able to fully demonstrate to our customers our advantages and professionalism in electrical connector production. Our focus on material selection and procurement, well-designed production processes, advanced manufacturing technologies, stringent quality control systems, traceability, and customization capabilities are all key factors that ensure the quality and performance of our connector products. We look forward to sharing more detailed information about our production processes and demonstrating how we can meet your requirements and deliver superior electrical connectors.

1. Material Selection and Procurement Process

2. Overview of the Production Process

Our Latest Articles

-768x542.png)

-1-768x542.png)

11-768x542.png)

-768x542.png)

XTH

We will do strict

Commercial confidential protection work for our customers

3 Professional laboratories

Professional laboratories and testing facilities ensure the maximum reliability of our electrical connector products.

Using the top grade material

We select high-quality raw material suppliers and strictly control the quality of raw materials through professional testing.

14 years of factory

We have many years of research and production experience, and can provide customers with a wide range of electrical connector series and customized solutions.

How can I offer professional electrical connectors?

Send Your Detailed Enquiry

Please provide us with more information about your requirements, including dimensions, quantity, and materials, so that we can accurately assess and assist you.

Product Design

You can send samples or product drawings. Even if you only have basic ideas, you can share them with us. We will collectively review and confirm the design and drawings you require.

Pilot Production With Samples

Validate the feasibility of the product design, assess the effectiveness of production processes, and conduct performance testing of the product.

Ensure Timely Delivery of Mass Production

We take care of the production phase and here is our promise: the right materials, the right quantity, the right printing, at the right time.

5.jpg)

6.jpg)

7.jpg)

8.jpg)

11-1024x919.jpg)

12-1024x919.jpg)

13-1024x919.jpg)

14-1024x919.jpg)