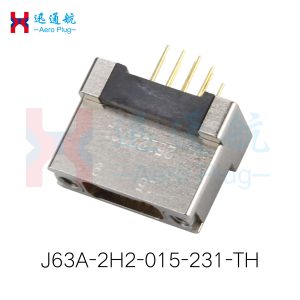

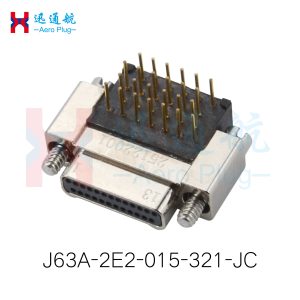

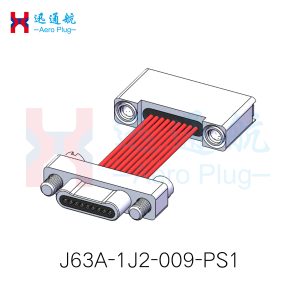

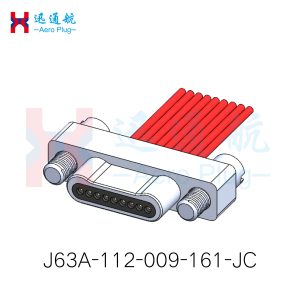

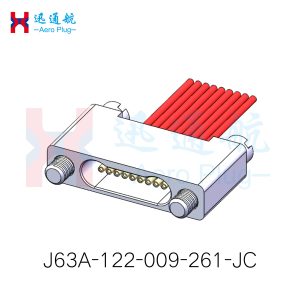

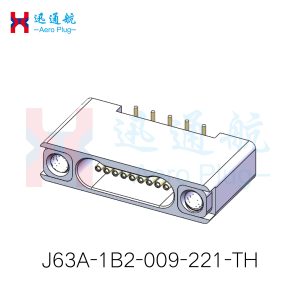

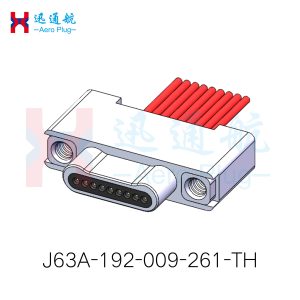

J63A Series Micro-Rectangular Electrical Connectors

The J63A Series connectors offer modular, ergonomic, robust, and reliable circular multi-pin connectors, suitable for applications requiring fast and secure push-pull latching. The Series B spring technology connectors are widely used in healthcare, broadcasting, industrial, research, motorsports, test and measurement, military and aerospace, machinery and robotics, information and networking, energy and infrastructure, and other fields. Additionally, they feature excellent compatibility with many leading suppliers.

Product Features:

■ Core configurations available: 9, 15, 21, 25, 31, 37, 51, 65, and 69 contacts;

■ Adopts twisted wire contact structure with a pitch of 0.635mm;

■ Compact footprint; plugs and receptacles mate via screw-nut threading, ensuring smooth mating/unmating and secure locking;

■ High density, small size, light weight, and high reliability;

■ Fixed configuration: plugs equipped with pins, receptacles with sockets; the free end is fitted with locking screws, and the fixed end with coupling nuts; the free end and fixed end are mated, aligned, and locked through screw-nut threading;

■ Executive Standard: GJB 7245-2011 General Specification for Shell-Located Ultra-Micro Rectangular Electrical Connectors;

■ Crimp-type products accommodate wires of 0.035mm².