In the rapidly evolving field of electronics, the selection of electrical wire connectors directly affects the stability of system operation. A suitable connector can ensure stable system operation, while enabling miniaturization, lightweight design and convenient operation; improper selection may lead to equipment failures, product recalls and increased maintenance costs.

The following will elaborate on the positive impact of electrical wire connectors that meet requirements on equipment from three dimensions: design, usability and cost structure, and provide cross-regional application selection references combined with the latest global industry trends.

I. High-Quality Connectors Ensure Stable Equipment Operation

The core criteria for connector selection are that the rated voltage, current and contact specifications match the application requirements. In fields such as new energy vehicles, 5G communications and industrial automation, it is necessary to ensure sufficient contact quantity, which can stably carry current load, and meet the requirements of high-frequency transmission and anti-interference.

The current-carrying capacity is jointly determined by the contact size and wire gauge; the rated voltage is affected by the contact spacing, insulation material properties and insulator structure. Global electrical connector industry standards are continuously upgraded, strengthening reliability and high-frequency performance requirements. When selecting, it is necessary to consider the target market and prioritize products that comply with the latest standards of the corresponding region.

Functionally integrated equipment needs to realize synchronous transmission of multiple types of signals through connectors, in which case customized hybrid connectors are required. Hybrid connectors can simultaneously transmit power and multiple signals, adapting to the needs of precision equipment. During installation or modification, attention should be paid to the wiring method and insulation treatment, and verification should be conducted to ensure compliance with specific industry standards.

II. Key Points for Precise Connector Selection

There is a wide variety of connectors, and selection decisions directly affect their functional adaptability. Combined with industry trends, selection should focus on three core directions: material, reliability and miniaturization.

1. Material Selection

Material is a core factor determining connector performance, mainly divided into plastic and metal categories, which affect reliability, weight, cost and environmental friendliness. Global green and low-carbon policies have promoted environmental protection materials to become the mainstream; European and American markets have more stringent environmental regulations, leading to a higher application ratio of environmental protection materials.

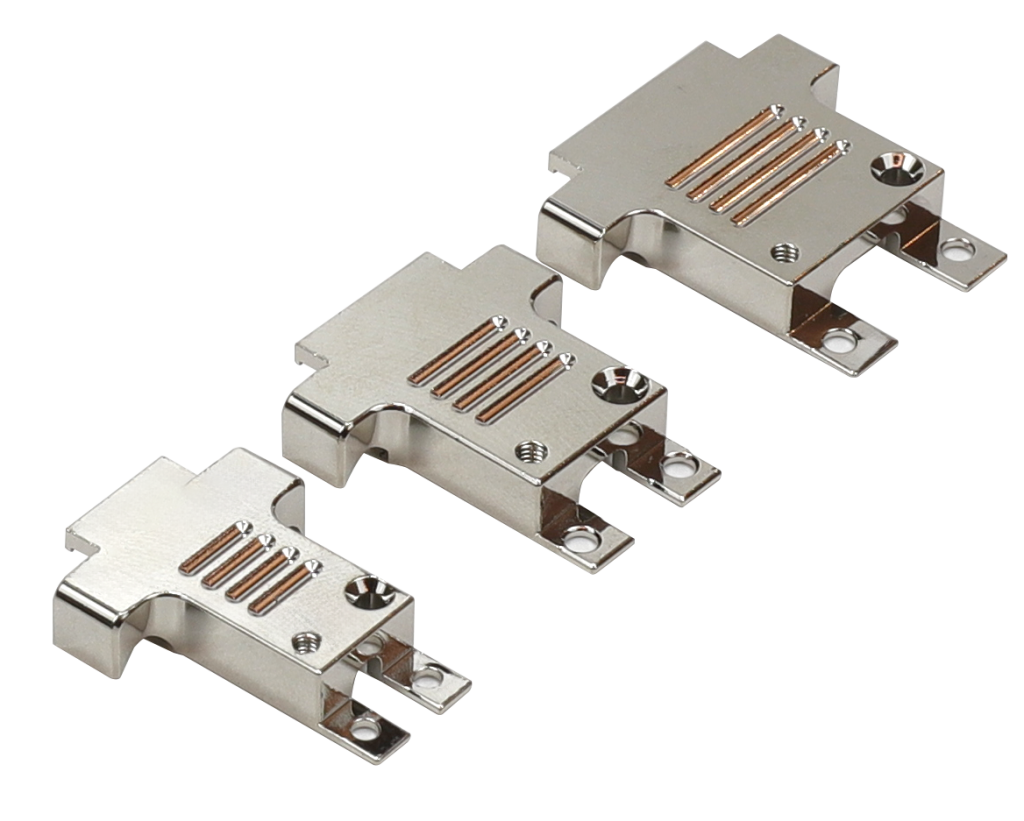

- For wear resistance and long service life, nickel-plated/chrome-plated brass connectors are preferred; high-performance copper alloys are suitable for micro terminals;

- For lightweight requirements, aluminum alloy connectors can be selected, adapting to weight-sensitive fields such as new energy vehicles;

- For corrosive environments (such as outdoor and marine equipment), stainless steel connectors are required;

- Plastic connectors should use engineering plastics with excellent high-temperature resistance and high-frequency performance, adapting to high-frequency scenarios such as 5G; relevant environmental protection and flame-retardant certifications should be completed according to the target market.

The insulation materials of various material connectors (including contact insulators, potting materials and O-rings) must pass tests to ensure compliance with the wide temperature range and anti-aging requirements of different regional scenarios.

2. Reliability Considerations

After confirming that the connection method, wiring process, sealing performance and material meet the standards, further evaluation of reliability is required to adapt to the harsh working conditions of emerging fields.

It is necessary to clarify the expected mating frequency of the connector and select matching products. All connectors are marked with rated mating life; for high-frequency mating scenarios (such as industrial automation and charging piles), products with high mating life should be selected.

Environmental adaptability is a key factor affecting reliability. There are significant differences in working conditions across regions: North American automotive connectors need to meet high anti-vibration requirements, European outdoor energy storage connectors need to pass high-standard salt spray tests, and tropical regions need to enhance high-temperature and high-humidity resistance. Automotive connectors must comply with the wide temperature range and EMC (Electromagnetic Compatibility) standards of the corresponding region, and outdoor energy storage connectors must meet high-level waterproof and dustproof requirements.

-1024x1024.png)

3. Adaptation to Miniaturization and Intelligence Trends

The trend of miniaturization and flexibility in the electronics field is significant, and the miniaturized design of connectors directly affects the integration and portability of equipment.

New types of miniaturized connectors can realize multi-functional integration, which are widely used in fields such as smartphones and high-end wearable devices. The application ratio of flexible connection structures in high-end wearable devices in European and American markets is relatively high.

In high-voltage and high-current scenarios, the detailed parameters of connectors are crucial, and it is necessary to compare pin size, quantity and functional characteristics. Miniaturized connectors have limitations: some cannot transmit power and signals simultaneously, and wiring is usually more difficult; pre-wired design can improve reliability. In addition, integrating sensing functions into high-end connectors has become a trend, which can monitor the connection status in real time and adapt to the needs of intelligent equipment.

III. Recommended Choice: Shenzhen Xuntonghang Electronic Technology Co., Ltd.

Against the background of global supply chain collaboration, brands with global technical adaptability have become the first choice for multinational enterprise procurement. As an international connector enterprise, Shenzhen Xuntonghang keeps up with global industry trends, with products covering new energy vehicles, 5G communications, industrial automation, medical electronics and other fields, complying with relevant domestic requirements as well as mainstream international standards and regional specifications.

Shenzhen Xuntonghang can provide customized solutions and a full range of products for general and high-end scenarios, with intelligent production capabilities, high product precision and reliability. Its products have passed multiple international authoritative certifications, adapting to global scenarios such as Europe, America, North America and Asia-Pacific. Choosing Shenzhen Xuntonghang can provide access to high-quality connectors that meet the latest global standards and global technical support, while balancing cost advantages and helping to expand the global market.

.png)

-1.png)