Although gold plating has long been regarded as the industry benchmark in electronics manufacturing, the recent continuous surge in gold prices, coupled with restrictions on cyanide-containing gold plating processes imposed by global environmental regulations (China mandates the phasing out of cyanide electroplating processes by 2026), has prompted numerous manufacturers to accelerate the search for more cost-effective and eco-friendly alternatives.

Boasting excellent electrical conductivity, as well as outstanding oxidation and corrosion resistance, gold is an ideal material for electronic electroplating applications. Since the COVID-19 pandemic, driven by multiple factors including escalating geopolitical conflicts, global liquidity easing, weakening US dollar, and increased gold purchases by central banks, the price of gold has maintained a strong upward trend. On January 14, 2026, the international spot gold price broke through USD 4,630 per ounce, hitting a record high of USD 4,636 per ounce. As of January 16, the London spot gold price remained stable at the high level of USD 4,602.55 per ounce, with a year-to-date increase of approximately 6% within less than half a month.

Key Considerations for Selecting Gold Plating Alternatives

When choosing alternative electroplating metals, it is essential to refer to the core properties that make gold the preferred option, with a focus on the following aspects:

- Excellent thermal and electrical conductivity (contact resistance must match application scenarios; high-end, low-resistance scenarios typically require ≤ 8 mΩ)

- Superior oxidation and corrosion resistance, suitable for working environments with high humidity and thermal cycling

- Non-magnetic properties to meet the requirements of precision electronic equipment

- Long service life, adaptable to plug-in applications and extreme working conditions

- Compliance with environmental regulations and compatibility with the trend of cyanide-free processes

Most alternatives with properties closest to gold come from the precious metal family. Precious metals, including gold, generally exhibit strong chemical inertness, along with excellent oxidation and corrosion resistance.

Several Mainstream Precious Metal Alternatives

Silver

Silver features exceptional electrical conductivity and outstanding contact resistance performance (an optimal choice for mid-range scenarios, capable of meeting the ≤ 8 mΩ requirement), while also possessing good corrosion resistance, making it a high-quality alternative to gold plating. Since the start of 2026, the silver price has fluctuated upward sharply. As of January 16, the London spot silver price stood at USD 91.721 per ounce, with a year-to-date increase of over 19%. Although still cost-effective compared to gold, its price has risen significantly from previous levels. Silver can also serve as a metal lubricant, making it highly suitable for electroplating threaded contacts or sliding contacts. However, it should be noted that silver coatings tend to form compounds such as silver sulfide, which can lead to decreased conductivity. The current sharp rise in silver prices is driven by multiple factors including expectations of Federal Reserve interest rate cuts, booming industrial demand (from sectors such as photovoltaics, new energy vehicles, and AI servers), widening supply gaps, and geopolitical risk aversion, showing a dual-driven characteristic of financial and industrial attributes.

Palladium

Palladium offers excellent electrical and thermal conductivity as well as corrosion resistance, gradually emerging as a favored alternative to gold plating. Among them, palladium-nickel alloy coating (PdNi80/20) delivers impressive performance: after 1,500 thermal cycles ranging from -55°C to 125°C, the contact resistance change rate is less than 15%, with stability significantly superior to traditional silver plating processes, making it suitable for high-end micro-rectangular connector applications. Palladium has higher hardness than gold and silver, with better wear resistance. In terms of price, palladium has a lower unit price than gold but higher than silver. Unlike gold, palladium can be directly used as a coating material for copper—gold coatings cannot prevent the penetration of copper atoms, whereas palladium coatings can endow cost-effective copper with palladium’s corrosion resistance properties.

Nevertheless, palladium’s heat resistance is inferior to that of gold, and it may experience discoloration and deformation under extreme high-temperature conditions. Additionally, palladium is not resistant to strong acid corrosion and is prone to cracking under stress. To reduce the risk of cracking, palladium is usually alloyed with metals such as nickel and cobalt, which can also reduce palladium usage and further save costs.

Rhodium

Rhodium has higher hardness than silver, gold, and palladium. It not only has excellent electrical conductivity but also can withstand strong acid corrosion, with stable contact resistance. Due to its outstanding wear resistance and high hardness, rhodium is an ideal choice for applications with strict requirements for wear resistance and hardness. Although rhodium’s unit price is lower than gold, it is higher than palladium, and its price fluctuations are also affected by the overall precious metal market trends.

Selecting the Optimal Gold Plating Alternative for Projects

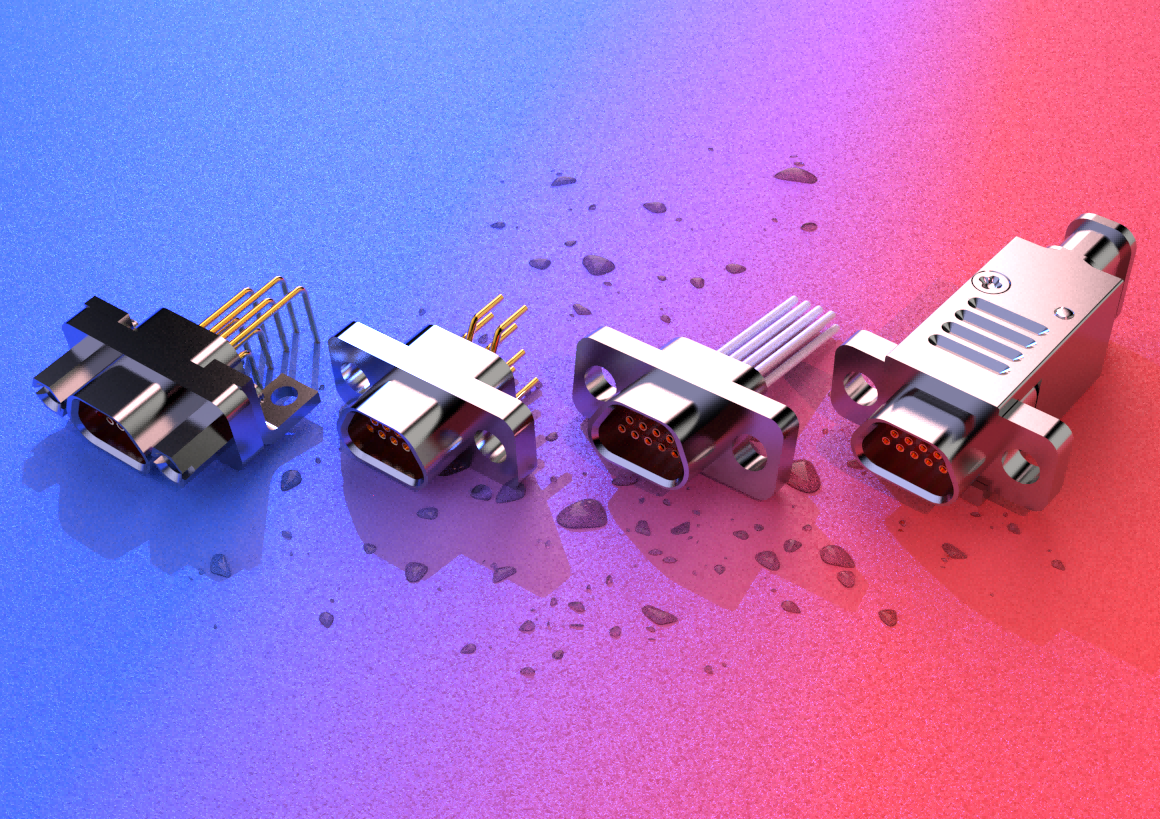

Besides gold, there are various options available for electroplating materials used in pins and contacts of electronic and electrical connectors. The specific material selected must be comprehensively determined based on project technical specifications, budget, market price fluctuation trends, and environmental compliance requirements, while matching core parameters such as contact resistance and cycle stability. The professional technical team of Shenzhen Xuntonghang Electronic Technology Co., Ltd. can provide professional selection analysis of gold plating alternatives and compliance process adaptation suggestions for signal or power micro-rectangular connectors.

Specializing in the R&D and manufacturing of micro-rectangular connectors, our company stands out from other manufacturers in the industry by achieving full-chain independent R&D from production equipment to core products. We have mastered the four key manufacturing processes of electrical connectors, namely equipment development, component fabrication, assembly, and wire harness processing, making us the only manufacturer of micro-rectangular connectors in the market with the capability of independent R&D and production of manufacturing equipment. Leveraging profound technical accumulation, we have built a complete industrial chain covering the manufacturing of power electronic components, supporting production of integrated circuits, and R&D of intelligent equipment. Our independently developed production equipment can be accurately adapted to new processes such as cyanide-free coating and palladium-nickel alloy plating, which not only ensures high precision and stability of products but also meets the stringent requirements for high reliability, miniaturization, and compound functionality of micro-rectangular connectors in high-end fields such as aerospace, intelligent equipment, and new energy through customized technological iteration. We will rely on our full-chain independent R&D advantages to help you design micro-rectangular connector products that fully meet your application requirements.

Contact us now to discuss your project needs. We look forward to cooperating with you!