Aerospace connectors, also known as avionic connectors, are specialized components designed for connecting electrical systems in aircraft. With the rapid development of global commercial aerospace, deep-space exploration, and low-altitude economy sectors, the design standards for such connectors are continuously upgraded. They must not only withstand extreme environments such as high altitudes, drastic temperature changes, and strong vibrations but also meet new-generation requirements including high-speed data transmission, lightweight design, and intelligent monitoring. As the “neural hub” of core on-board systems such as navigation, control, and communication, their reliability directly determines the operational safety and mission success of aircraft, making them indispensable core foundational components in the aerospace industry.

Combining the latest industry trends, this article will elaborate on the common types, core applications of avionic connectors, and their key roles in harsh aerospace environments.

I. Core Roles of Aerospace Connectors (Latest Upgraded Positioning)

Aerospace connectors undertake multiple critical missions, each of which is vital to the reliability and safety of aircraft systems. With technological iterations, their functional positioning continues to expand:

1. Power Distribution: Balancing High Power and Lightweight Design

Connectors serve as the hub of the aircraft’s power distribution network, responsible for stably transmitting electrical energy from power sources such as generators and batteries to core loads including avionic equipment, lighting systems, and propulsion systems. Current mainstream products feature excellent electrical performance. Meanwhile, by adopting new materials such as silicon carbide-reinforced aluminum matrix composites, structural weight reduction is achieved on the premise of ensuring power supply stability. Some models are suitable for lightweight equipment requirements such as low-orbit satellites, light helicopters, and low-altitude aircraft. Among them, relevant plastic-housed quick-lock rectangular connectors have formed international standards and possess good protection performance.

2. Data Transmission: Supporting High-Speed and High-Frequency Transmission Requirements

High-speed and highly reliable data connectors are crucial for maintaining the performance and data integrity of aerospace systems. Under the current technical system, mainstream products already support high-speed transmission, high-end models can achieve higher-order high-speed transmission, and some cutting-edge products have completed relevant technical verification. They can realize low-loss and low-interference data transmission, which is indispensable for precise navigation and telemetry data transmission in deep-space exploration. Meanwhile, through differential pair structure design and impedance matching optimization, signal crosstalk is effectively reduced, with excellent crosstalk suppression capability.

3. Signal Routing: Precisely Adapting to Intelligent Sensing Systems

Aerospace connectors are responsible for the transmission and distribution of various signals, including control command signals, sensor acquisition signals, and feedback signals. With the intelligent upgrading of aerospace equipment, they have achieved in-depth integration with MEMS intelligent sensors. Through embedded sensing modules, key parameters can be monitored in real-time, fault risks can be warned in advance, ensuring that the aircraft can respond accurately to various operational commands and significantly reducing the probability of system-level failures.

4. Communication System Guarantee: Consolidating Global Interconnection Links

Robust connectors are the foundation for maintaining unobstructed communication links of aircraft, ensuring clear and reliable global communication between the aircraft, ground control centers, crew members, and other aircraft. In the intensive low-orbit mega-constellation networking projects, RF connectors, as core components, have achieved excellent radiation resistance through optimized design, ensuring stable communication links in complex space environments, which is of great significance for flight safety and coordinated scheduling.

5. Avionic System Integration: Facilitating Modular Collaboration

Connectors support the integrated linkage of multiple avionic systems, enabling collaborative work of different components. For example, connecting flight management systems, autopilots, and display panels to realize integrated control and management of the aircraft’s avionic suite. Currently, modular design has become the industry mainstream, and rapid docking of various systems is achieved through standardized interfaces, greatly improving equipment R&D efficiency and maintenance convenience.

6. Maintenance and Upgrade Support: Adapting to Full-Lifecycle Management

Aerospace connectors adopt modular and easy-to-plug design with long plug-in life, greatly facilitating the maintenance and upgrade of aviation systems. Combined with digital twin technology, by constructing virtual prototypes to simulate the multi-physics field coupling behavior of connectors throughout their lifecycle, potential weak links can be identified in advance, maintenance strategies can be optimized, minimizing aircraft downtime and ensuring it is always in airworthy condition.

II. Common Types of Aerospace Connectors and Application Upgrades

The following types of connectors jointly support the reliability and functionality of aerospace systems, with the latest technological breakthroughs in materials, processes, and performance:

1. Circular Connectors: Main Choice for Deep-Space Exploration

Circular connectors are widely used in aerospace applications due to their robust structure and easy operation. With a cylindrical shape, they can integrate multiple pins to transmit different electrical signals and provide stable connections in harsh environments. Current mainstream models have achieved improved high-temperature resistance and resistance to fuel and salt spray erosion by adopting thermoplastic materials with excellent chemical resistance such as high-mechanical-strength PEI (polyetherimide). Meanwhile, they possess excellent vacuum sealing levels, making them the main connector type for deep-space exploration missions such as lunar exploration projects and asteroid sample return. They are widely used in avionic equipment, control systems, and power distribution systems.

2. Rectangular Connectors: Preferred for High-Density Integration

The advantage of rectangular connectors lies in their ability to accommodate high-density contacts in a compact space, making them particularly suitable for scenarios with limited space but requiring multiple connections. With the upgrading of miniaturization requirements, current products further improve contact density through ultra-fine precision structure design. Meanwhile, high-performance insulating materials such as LCP (liquid crystal polymer) are adopted to balance insulation reliability and lightweight requirements. Due to their high reliability and space utilization, they are widely used in cockpit display equipment, communication systems, and flight control units, especially suitable for high-density interconnection scenarios of commercial satellites. Relevant power supply rectangular connectors have formed international standard specifications.

3. RF Connectors: Core Guarantee for High-Frequency Communication

Radio Frequency (RF) connectors are core components of aircraft communication systems, radar, and navigation equipment. Current products further reduce signal loss and interference through optimized structure design and material selection, ensuring stable and reliable high-frequency communication quality. Common types include SMA, BNC, TNC, etc. Among them, high-end models can adapt to higher frequency ranges, meeting the high-speed data interaction needs in low-orbit mega-constellation networking. Different types are precisely adapted to different frequency ranges and application scenarios.

4. Fiber Optic Connectors: Core Choice for Large-Bandwidth Transmission

Fiber optic connectors have continuously increased their application proportion in the aerospace field due to their large transmission capacity and resistance to electromagnetic interference. On the premise of maintaining the advantage of high bandwidth, current products have achieved better adaptability to extreme environments, capable of withstanding space radiation and drastic temperature changes. They are widely used in on-board data networks, in-flight entertainment systems, and high-end communication systems, making them an ideal choice for long-distance and large-capacity signal transmission in aircraft, especially suitable for inter-satellite link interconnection needs of commercial aerospace.

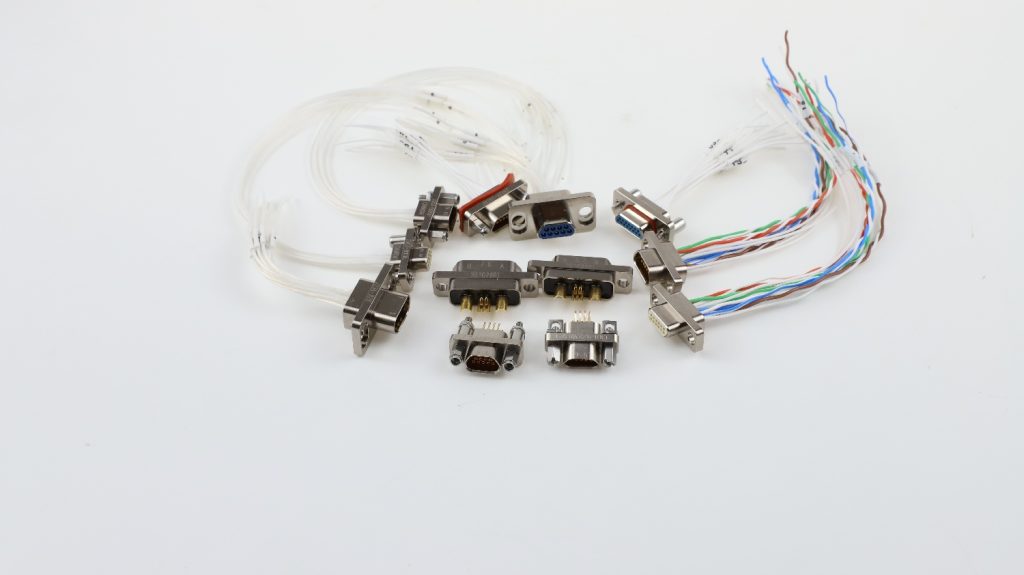

5. D-Sub Connectors: Upgraded Anti-Interference Performance

D-Sub connectors are characterized by their unique D-shaped metal shield, which not only enhances mechanical stability but also effectively reduces electromagnetic interference. Current upgraded models optimize shielding structure and plating processes to ensure anti-interference performance while reducing precious metal dependence and controlling costs. Such connectors are mostly used for data transmission and control signal transmission in avionic systems, with various sizes and pin configurations, enabling flexible adaptation to various aerospace application needs.

III. Explore Shenzhen Xuntonghang’s High-Reliability Solutions Now!

Shenzhen Xuntonghang is deeply engaged in the aerospace connector field, closely following industry technological trends. With independent innovation capabilities and strict quality control systems, it focuses on serving the aerospace connection sector. The company’s products cover core series of aerospace connectors such as circular, rectangular, and RF connectors, strictly complying with relevant domestic and international high standards. Core performance indicators have reached advanced industry levels, with excellent electrical performance and environmental adaptability. Some high-end models further realize high-speed transmission and intelligent condition monitoring functions, perfectly adapting to high-end application scenarios such as deep-space exploration, commercial satellites, military aircraft, and low-altitude aircraft.

Relying on the core advantages of independent R&D and independent production, Shenzhen Xuntonghang can provide customized connector solutions, optimizing material selection and structural design according to different mission requirements, while having significant cost-effectiveness advantages.

Welcome to contact us to learn how cutting-edge technologies can empower your aerospace systems and drive business development! You can also request a quote to get started.

.png)

-1.png)