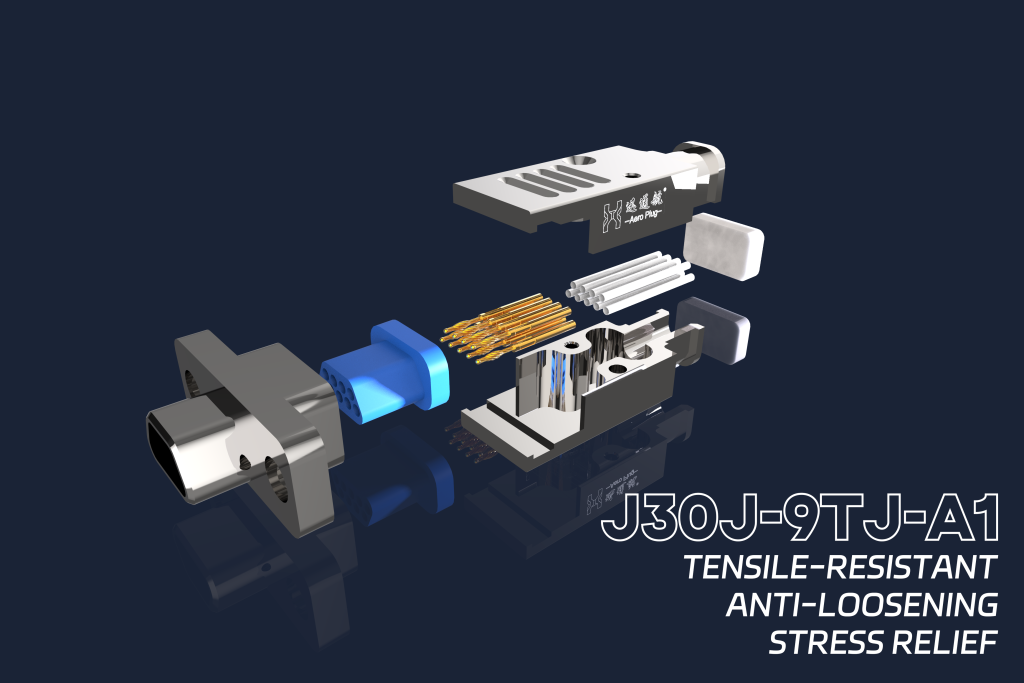

In the field of high-end equipment such as aerospace, medical electronics, and military equipment, where strict requirements are imposed on space constraints, weight control, and connection reliability, high-density and miniaturized electrical connection solutions serve as the core foundation for ensuring system performance. As a core product developed with dedicated focus by our company, the J30J Series Micro-Rectangular Electrical Connectors have become the preferred connection components for high-end electronic equipment, relying on precise structural design and excellent performance.

Core Product Positioning

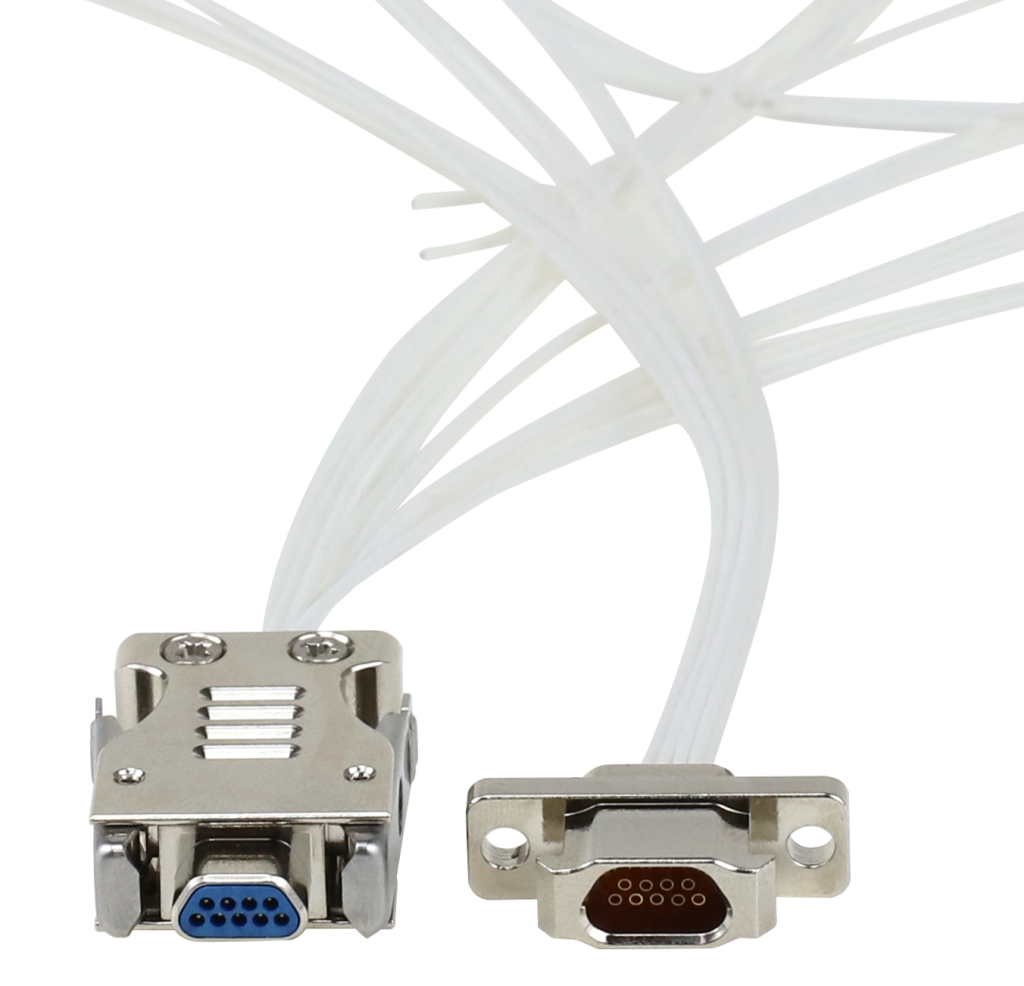

Focusing on miniaturized and high-density electrical connection requirements, the J30J Series Micro-Rectangular Electrical Connectors are specifically designed for space-constrained and weight-sensitive electronic systems. They can realize the integrated transmission of multi-channel signals and low-power energy, effectively addressing the pain points of traditional connectors such as excessive space occupation and complex wiring in high-end equipment, and providing key support for the integrated upgrading of equipment.

Core Technical Advantages

1. High-Density Integration Design with Excellent Space Utilization

Adopting a micro-rectangular packaging structure, it achieves high-density arrangement of contacts within a limited installation space, with the number of contacts covering dozens to hundreds of core specifications. Compared with traditional connectors, the contact arrangement density is increased by more than 50% under the same installation size, which significantly simplifies the internal wiring structure of the equipment, facilitates the lightweight and miniaturized integrated design of electronic systems, and reduces the overall weight load of the equipment.

2. High-Reliability Connection Performance and Strong Environmental Adaptability

Employing an elastic mating contact structure, it exhibits excellent contact stability, with a mating life of more than 500 cycles, continuously ensuring low contact resistance and signal transmission integrity. The product is equipped with an all-metal shell, featuring excellent electromagnetic interference (EMI) shielding performance, which can effectively resist interference in complex electromagnetic environments and ensure the stability and safety of signal transmission. Meanwhile, some models integrate a dustproof and sealing structure with sealing rings, which can meet the usage requirements under harsh working conditions such as humidity and salt spray, expanding the scope of applicable application scenarios.

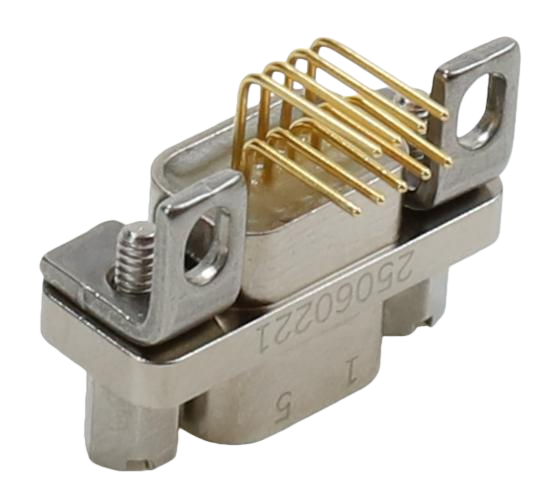

3. Precision Material Selection and Stable Process Guarantee

The contacts are made of gold-plated copper alloy, which combines excellent electrical conductivity, corrosion resistance, and wear resistance, capable of reducing contact loss and extending the service life of the product. The shell is made of high-strength aluminum alloy, which, after precision machining and surface treatment, ensures structural mechanical strength while achieving lightweight, and can withstand the test of mechanical environments such as vibration and impact. The product supports various standardized connection processes such as crimping, and has good interface compatibility, adapting to different system integration requirements.

Application Field Coverage

Relying on excellent comprehensive performance, the J30J Series Micro-Rectangular Electrical Connectors are widely used in aerospace equipment (such as UAV flight control systems, satellite navigation modules), medical electronic instruments (such as portable diagnostic equipment, surgical instrument control units), military electronic equipment (such as radar systems, electronic warfare equipment), and high-end industrial control equipment (such as precision servo drives, AGV controllers) and other fields. Typical application cases show that after adopting this series of connectors in the main control module of a certain type of UAV, the overall weight of the connection components is reduced by 30%, the system integration efficiency is significantly improved, and the endurance performance of the equipment is indirectly optimized.

Support from Enterprise R&D Strength

The company deeply engages in the R&D and production of micro-rectangular connectors, focusing on the technological iteration and performance optimization of the J30J Series products. With a professional R&D team, a precise production and manufacturing system, and strict quality control processes, it ensures that each product meets the reliability requirements of high-end equipment. From product design, material selection to production inspection, it implements industry standards throughout the entire process, providing customers with customized connection solutions that combine stability and adaptability.

.png)

Core Selection Guidelines

During the selection process, it is recommended to focus on three core dimensions to ensure the precise matching of the product with the application scenario:

- Number of Contacts: Determine the appropriate core specification according to the number of signal and energy transmission channels of the system;

- Environmental Parameters: Clarify the operating temperature range, humidity conditions, and whether dustproof and waterproof protection level requirements are needed;

- Installation and Connection Methods: Select appropriate connection types such as crimping in combination with the equipment assembly process.

With the core advantages of high density, high reliability, and miniaturization, the J30J Series Micro-Rectangular Electrical Connectors continuously empower the upgrading and iteration of high-end electronic equipment. The company will always focus on the technological R&D and product innovation in the field of micro-rectangular connectors, providing more competitive electrical connection solutions for customers in various industries.

.png)

-1.png)