The characteristics of core components and manufacturing processes are crucial to product performance and provide support for product selection. In the entire production system of electrical connectors, the characteristics of core components and manufacturing processes directly determine the final performance of the product. From the precision forming of contact elements to the material selection of housings, every link must adapt to actual application requirements. Mastering these manufacturing key points can provide important support for designers and engineers in product selection.

As the core component for signal and power transmission, contact elements are made of conductive metal, manufactured by stamping or CNC machining, and require subsequent quality verification. As the core component of electrical connectors for signal and power transmission, contact elements must be made of conductive metal materials. Their manufacturing mainly relies on two core processes: stamping and CNC machining. Among them, the stamping process uses thin metal strips as raw materials. Through high-speed automatic stamping machines combined with special molds, the metal strips are gradually sheared and bent to finally form finished products with high dimensional accuracy and stable mechanical properties. Subsequently, sensors and camera vision systems are required to complete quality verification.

Connector inserts are made of non-conductive materials to separate pins from housings, their types vary with housing materials, and strict defect detection is required. Connector inserts play a key role in separating pins from the housing and are made of non-conductive materials. For metal housing connectors, inserts are mostly made of rubber or silicone materials, which can effectively avoid electrical problems such as leakage and clearance, and prevent adverse effects on contact functions. For connector housings made of plastic or other non-conductive materials, the housing itself can also have the function of an insert, but this feature may limit the number of injection molding processes. To ensure the quality of inserts, visual inspection and optical inspection are required to check for potential defects such as internal stress, uneven thickness, deformation, and socket blockage.

Plastic and metal connector housings adopt different manufacturing processes, and metal housings require additional electroplating treatment. As the protective and positioning structure of electrical connectors, housings are mainly divided into two categories: plastic and metal, and their manufacturing processes are significantly different. Plastic housings generally adopt injection molding process: first, plastic pellets are melted into liquid polymer at high temperature, injected into a custom mold for cooling and solidification, and then demolded and taken out after complete molding. Metal housings are formed by die casting or machining. After forming, electroplating treatment is required – common methods include barrel plating, rack plating, vacuum plating, plasma plating, etc. The main plating materials are olive drab cadmium, nickel, and gold, aiming to improve conductivity, extend service life, and prevent rust and wear.

Strict post-electroplating inspection and full-process quality control are the key to ensuring connector quality. After electroplating, the housing must undergo strict quality inspection: X-ray fluorescence is used to detect the integrity and thickness uniformity of the electroplating, and visual inspection is used to check for cracks, pits, blisters, excessive edge accumulation, and uneven appearance to ensure the finished product meets quality requirements. In fact, quality control runs through the entire manufacturing process of electrical connectors. All components such as housings, inserts, and contact elements must be individually tested. During the subsequent assembly stage, a second comprehensive verification is required to ensure the product meets the established quality benchmarks and specifications.

Electrical connectors can achieve reliable power and signal transmission with significant advantages, and the materials of their terminals and housings need to be selected according to application requirements. From the perspective of basic functions, the core value of electrical connectors is to provide reliable connections and realize power and signal transmission through the cooperation of male and female terminals. Compared with traditional welding or wiring harness solutions, it has significant advantages: strong flexibility, easy assembly, and support for repeated plugging and unplugging, facilitating subsequent upgrades, maintenance, or temporary use. In addition to protecting internal components from external interference, its housing can also ensure the stability of electrical connections. The material selection must be determined according to specific application requirements; terminals are mostly made of copper or other conductive metals, and their surfaces are often plated with gold, tin, or other coatings to enhance conductivity and extend service life.

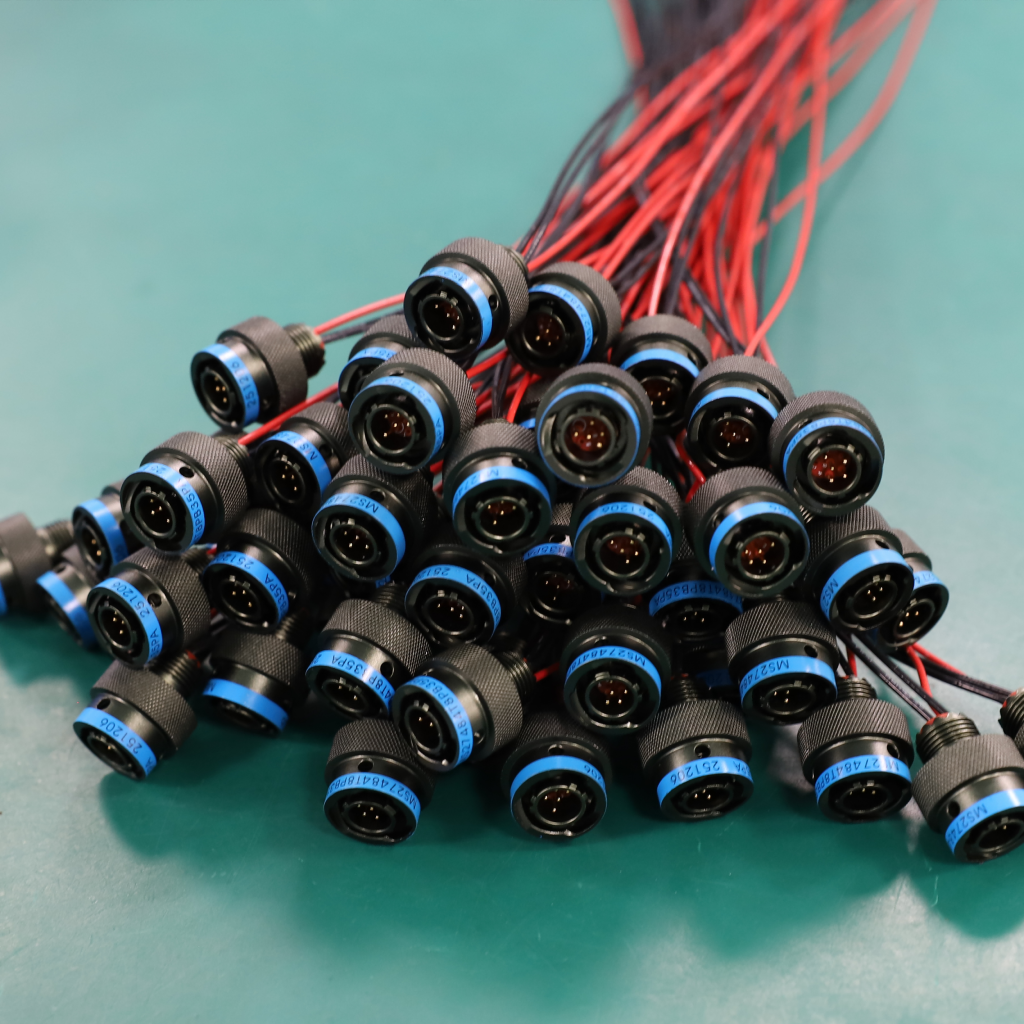

Assembly is the final link in connector manufacturing, with customization attributes, and distributors can also participate in this process. Assembly is the final link in the manufacturing of electrical connectors and also a key stage for product customization. Different manufacturers can match different types of housings, inserts, and contacts according to needs to form products suitable for diverse scenarios. It is worth noting that distributors can also deeply participate in the assembly stage. For example, (XTH) Shenzhen Xuntonghang Electronics Technology Co., Ltd. provides such customized services for customers. With sufficient inventory of available components, it can quickly complete the production and delivery of connector products.

5

Electrical connectors are widely used and continuously iterated, and understanding their manufacturing logic is crucial for accurate selection. There are many types of electrical connectors on the current market. Meeting performance requirements is the basic requirement of products, but the manufacturing and assembly processes also profoundly affect the final product quality, production cycles, and customer application effects. Today, electrical connectors have been widely used in various electronic products. To adapt to technological progress, meet new industry standards, and withstand harsh application environments, they are constantly iterating and upgrading, while taking into account design objectives such as usability, cost-effectiveness, and sustainability. In-depth understanding of their manufacturing logic is crucial for accurate selection and improving the overall performance of products.

.png)

-1.png)